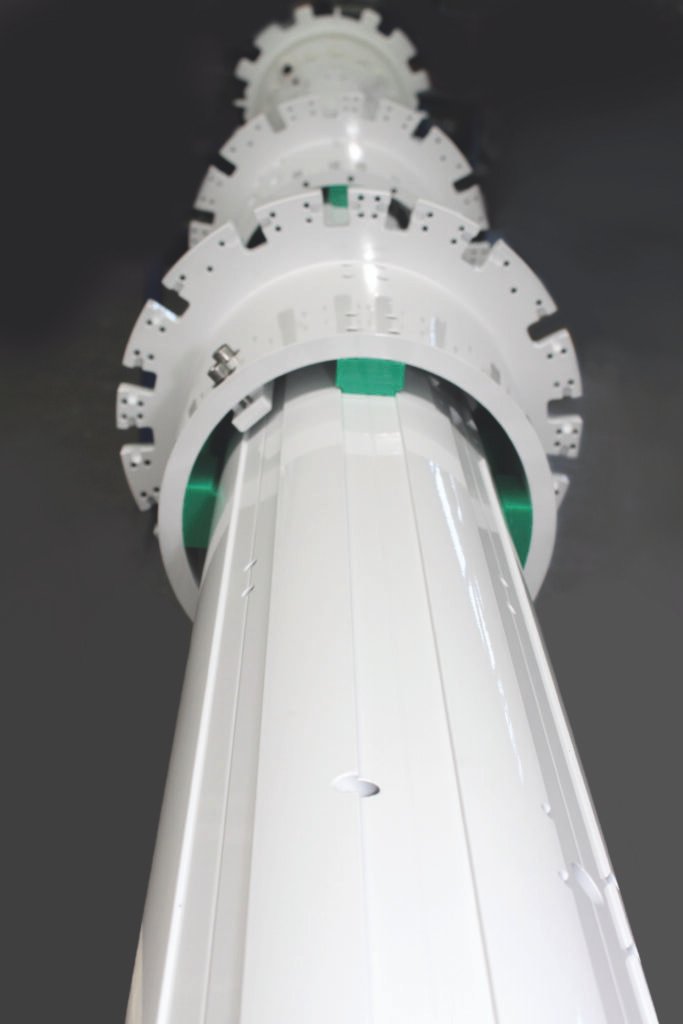

The Heart of it All

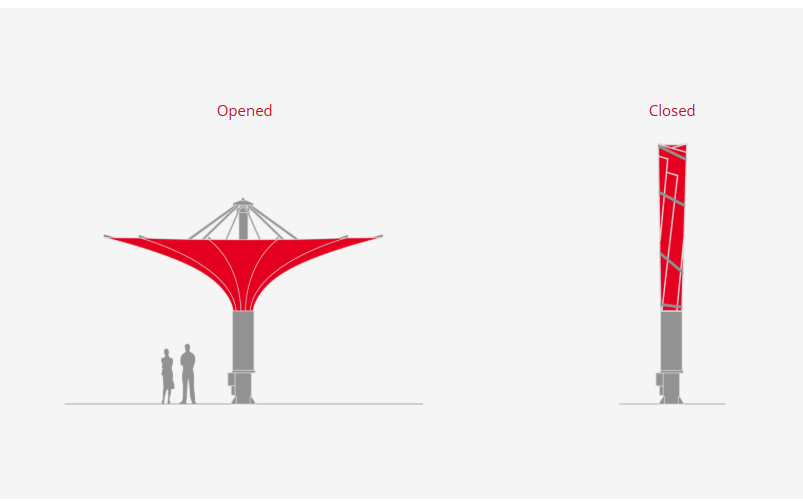

Technically Largo is our most elaborate model. The impressive, large-size parasol has an unusual and elegant shape opening upwards like a tulip. The underlying principle of a parasol is literally turned »upside down«. Only the textile covering and the cladding of the center pole are visible. Other technical details are nearly all hidden in the parasol. Pure premium beauty. The parasol’s sturdiness is guaranteed for wind speeds of up to a max. of 130 km/h.

- Unique and aesthetic design

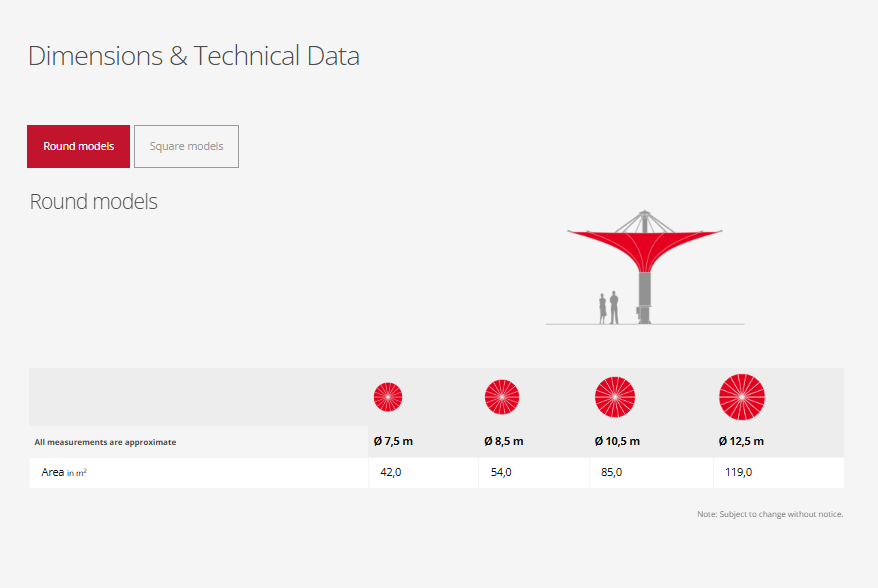

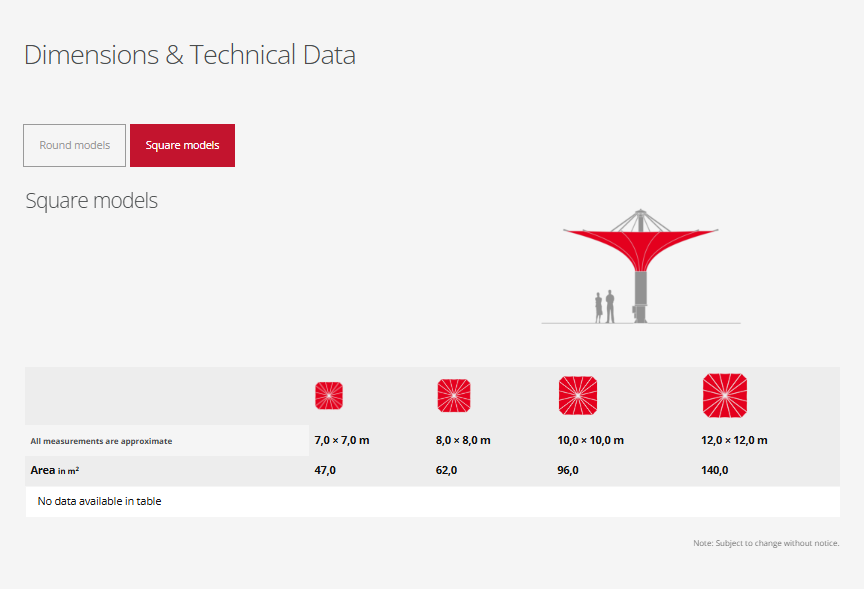

- Round and square roof shapes

- Interior, indirect lighting

- Installation with drainage and power supply

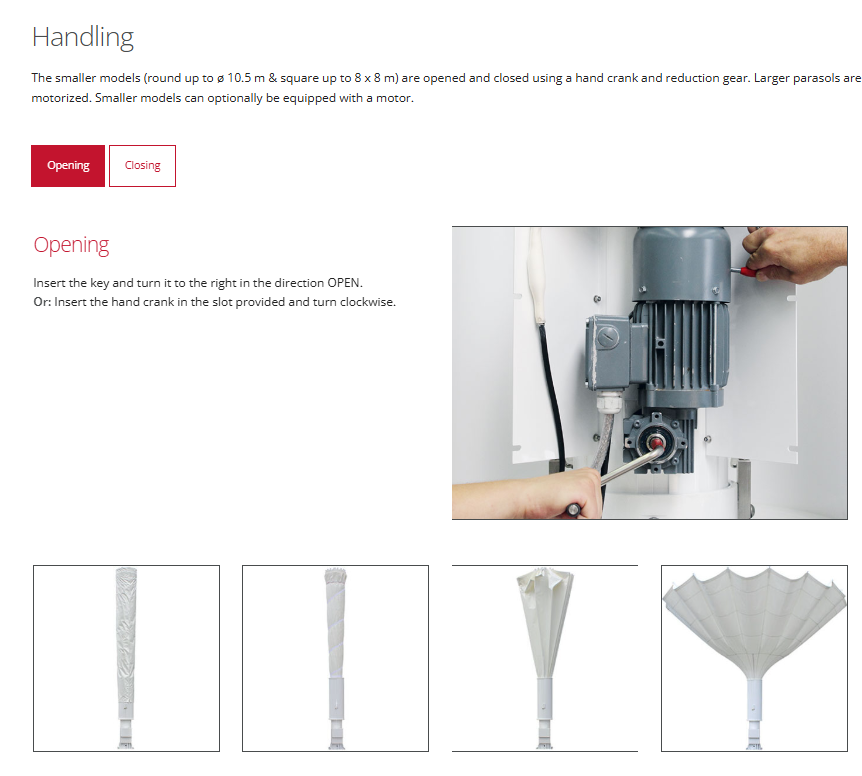

- Telescopic opening and closing

- Parasol weight approx. 800 – 2,350 kg

- Depending on model opening and closing per crank or geared motor

- Easy handling

- Optimal fabric tension

- High-quality, technical components

Textile Membranes

No matter your choice of fabric, the resulting textile membranes combine all the attributes of a durable and sustainable product. These include next to the high-quality appearance numerous technical functions.

Brand Name: betex® 05 | Fabric exclusively crafted for Bahama

100% polyester fabric with top transparent coating

Grammage of approx. 200 g/m2

Excellent UV-protection UPF 50+ protects against UV radiation (exception: snow 9577)

High degree of fabric lightfastness (i.e. fading) (DIN EN ISO 105-B02 Class ≥ 6–7)

High waterproofness, pressure resistance (DIN EN 20811, ISO 811 | Water column ≥ 100 mbar, 1.000 mm)

Low moisture absorption, dries quickly

High temperature resistance (DIN 53361 from -30°/+90°C)

Excellent friction resistance (DIN EN ISO 105-x12 | Class ≥ 4–5)

High tear resistance due to high thread count

Durable, tailor-made and dimensionally stable with perfect membrane tension

Sustainable and environmentally friendly fabrics with the OEKO-TEX 100 Standard, Class 1

Exchangeable and washable one-piece membranes

25 contemporary colors (custom colors upon request)

Printable with the most modern printing process

Brand Name: Precontraint 302

PVC coated Polyester 550 Dtex. SERGE FERRARI PRECONTRAINT® coating technology

Grammage of approx. 480 g/m2

Excellent UV-protection UPF 50+ protects against harmful UV radiation

High degree of fabric lightfastness (i.e. fading) (DIN EN ISO 105-B02 | Class ≥ 7–8)

Heat-sealed segments, 100% waterproof

High temperature resistance (DIN 53361 from -30°/+70°C)

Fire retardant (DIN 4102-B1)

Exceptional surface stability and tear resistance

Durable, robust, dirt-repellant and stable in all weather conditions

Own cleaning possibility due to increased dirt accumu- lation through leaves, tree sap, bird-droppings, car exhaust or dust

Recyclable

25 contemporary colors (custom colors upon request)

Printable with the most modern printing process

Brand Name: swela Sunvas uni-colored and striped | ZebraS

100% polyester fabric with dirt and water repelling impregnation

Grammage of approx. 310 g/m2

Excellent UV-protection UPF 50+ protects against harmful UV radiation

Highest degree of fabric lightfastness (i.e. fading) (DIN EN ISO 105-B02 | Class ≥ 7–8)*

High waterproofness, pressure resistance (EN 20811, ISO 811 | Water column ≥ 35 m bar, 350 mm)

Weather fastness (DIN EN ISO 105-B04 | Class ≥ 7–8)*

Excellent friction resistance (DIN EN ISO 105-x12 | Class ≥ 4–5)

High tear resistance

Distinctive surface feel

Not printable

Color Chart betex®05

Color Chart Procontraint 302

Sustainability and Environmental Compatibility

The betex®05 fabric, exclusively crafted for Bahama, and the resulting textile membrane are certified exclusively according to the OEKO-TEX 100 standard, Class 1 which is awarded by independent institutions. Class 1 meets the demands of baby clothing with skin contact.

The OEKO-TEX pollutant test corresponds to the respective intended use of the textiles and materials. In Germany there are clear and reliable criteria for environmental compatibility and sustainability. Bahama demands of its products that every defect or damaged part can be replaced.

Made in Germany

Bahama’s customers always refer back to the great importance of our German production facilities. »Made in Germany« is still a unique selling point and a reason to buy. Bahama‘s full range production facility is located in Germany.

The combination of the highest quality materials and structural features allows Bahama to guarantee the wind stability of its products, depending on the model, up to 130 km/h. In addition to the technical details of the parasol, it is especially the lightfastness of the fabrics’ colors, the waterproofness and grammage as well as the water column of the textile membranes which make Bahama top of its class. Trust is placed in Bahama by luxury hotels such as the Burj Al Arab in Dubai, the Hotel Sacher in Vienna and the Dalí Museum in St. Petersburg, USA.

Service

Service greatly influences the life span of a parasol. The exchangeable textile membrane of a Bahama parasol can – after being exposed to all sorts of weather conditions for years – be cleaned or replaced. Our service makes a full technical and general overhaul of the product such that they not only look attractive, but can defy the strongest of winds.

No matter where you need Bahama’s service, the Bahama team or one of our expert partners will be glad to help – worldwide.

UV-Protection

Analogous to the sun protection factor/SPF all textiles are labeled with an ultraviolet protection factor/UPF. Built into the fabric it protects against hazardous UV radiation. Bahama uses the fabric brand betex®05 for the production of its parasol textile membranes. This material fulfills the requirements for UPF50+, which indicates an »excellent« dermatological UV protection factor and allows less than one fiftieth (<2%) of the UV radiation through the textile membrane onto the skin.